1A-Superfinishing Films

DIAMOND

Finishing Film

DIAMOND

Lapping Film

ALUMINUM OXIDE

Finishing Film

ALUMINUM OXIDE

Lapping Film

SILICON CARBIDE

Finishing Film

SILICON CARBIDE

Lapping Film

1A – THE CONVINCING QUALITY

QUALITY DESCRIPTION:

- constant grit sizes and grit shapes

- close grit distribution

- strong bonding of the resin bond layer on the base foil

- very good bonding of the grit through a resin bond adhesive agent

- uniform grit distribution

- avoiding of agglomeration – no clumping of several grains

- sufficient strength of the polyester base material (PET base foil)

To achieve a well-defined and constant, repeatable surface, stable working parameters are necessary. Contact pressure and therefore the stress of individual grit will be achieved through the use of polyester foil as base material.

This foil will be coated with abrasive, which will be selected according to CIS-norm (Calibration for industrial standards) and then fixed with a special bonding.

Control values in use:

- contact pressure

- hardness of the draw roll

- feed of the superfinish attachment

- speed of film feed

- grit size of the film

- oszillation rate

- rotational speed of the work piece

SUPERFINISHING FILM – PRODUCTION:

Finishing film typically consists of the backing material, the abrasives particles and the bonding agent:

Backing material:

A tear and stretch resistant base film, usually polyester foil (3Mil = 75µm, 4Mil = 100µm or 5Mil = 125µm).

Abrasives:

The particles are selected according to their dimension and slurry coated (LF) or electrostatically spread (FF) on the base film.

Bonding agent:

A bonding agent based on synthetic resin secures the abrasive particles to the backing material.

Fixing layer:

To stabilize the composition, an additional adhesives agent will be sprayed on after electrostatical deposition of the grit.

1A-DIAMOND FINISHING FILM

1A-DIAMOND FINISHING FILM

… is a with concentrated diamond abrasives, precision coated, water resistant and tough polyester film. The bonding of the abrasive particles provides flexibility and a steady hold on the film substrate. The resin bond between the particles and the film ensures an absolute permanent and consistent processing of the surface. Our 1A-Diamond Finishing Film offers a repeatable and precise finish on hard and extremely hard surfaces and provides an aggressive grinding pattern..

Application areas:

- materials: ceramics, high alloyed materials, hard metall coatings, glass, marble, granite, porcelain

- work pieces: hard coated rollers and shafts, glas parts, fiber optic connectors, metallographic

- industries: roller manufacturer, roller coating services, automotive industry, print- and paper industry,

stone industry, glass industry

Girt sizes in µm

9 · 15 · 20 · 30 · 40 · 60 · 80 · 125

Abrasives: diamond – electrostatically spread

Backing material: polyester foil (4Mil = 100µm)

Further information on request.

Our 1A–Diamond Finishing Films should be generally used in combination with common cooling lubricants or with water.

1A-DIAMOND LAPPING FILM

1A-DIAMOND LAPPING FILM

…offers a reliable finish on hard surfaces. The backing material is a water resistant, tough and consistent polyester film. The resin bond between the particles and the film ensures the utmost repeatability and permanent and consistent surface processing. The integrated diamond micron powder bonds firmly on the polyester film substrate. 1A-Diamond Lapping Film is ideal for fine lapping and polishing of the hardest metallic or ceramic surfaces. It offers a repeatable and precise surface finish on extremely hard and hardened materials.

Application areas:

- materials: carbides, metals, ceramics, glass, rocks and minerals, titanium, gem stones

- work pieces: rollers, fiber optic connectors, magnetic heads, metallurgical devices, engine and machine parts, computer hard discs, chrome-plated work pieces, high alloy surfaces

- industries: roller manufacturer and roller coating services, automotive, ophthalmic, fiber optic, ceramic and computer peripherals

Grit sizes in µm

0,5 · 1 · 3 · 6 · 9 · 12 · 15 · 30 · 40 · 45 · 60 · 80 · 100

Abrasives: diamond – slurry coated

Backing material: polyester foil (3Mil = 75µm)

Further information on request.

Our 1A–Diamond Lapping Films should be generally used in combination with common cooling lubricants or with water.

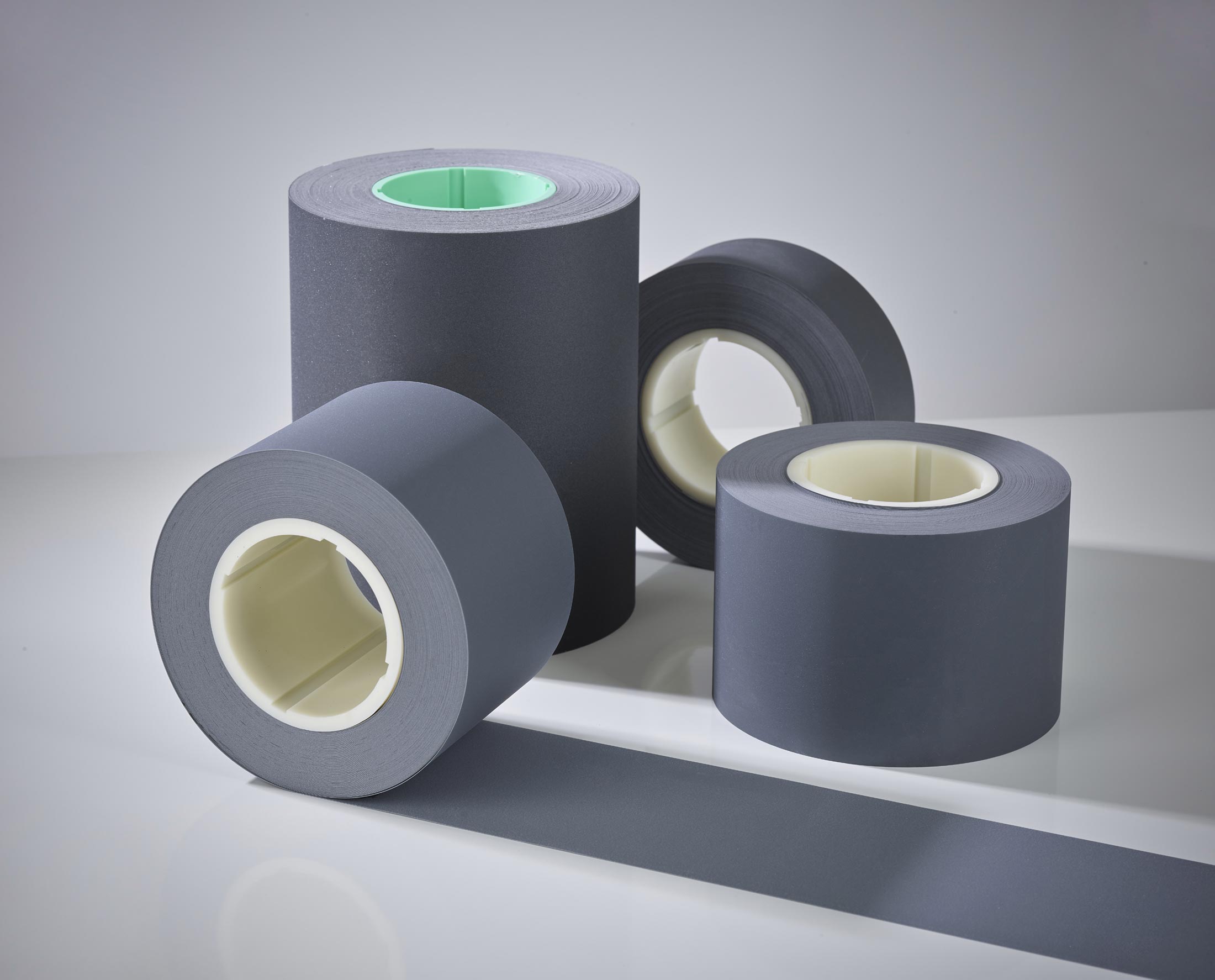

1A-DLF Rolls

abrasive side:

outside (standard) | inside also possible

dimensions:

standard: 100mm x 16m

other sizes according to customers specification

core:

3 inch with notches or 1 inch

1A-DLF Sheets

Our 1A–DLF Sheets are fine grinding tools, to reach precise surfaces on extremly hard and hardened materials. Sheets are mostly used on lapping machines or for manual operations.

backside:

self adhesive | not self adhesive

standard: 230mm x 280mm

other sizes according to customers specification

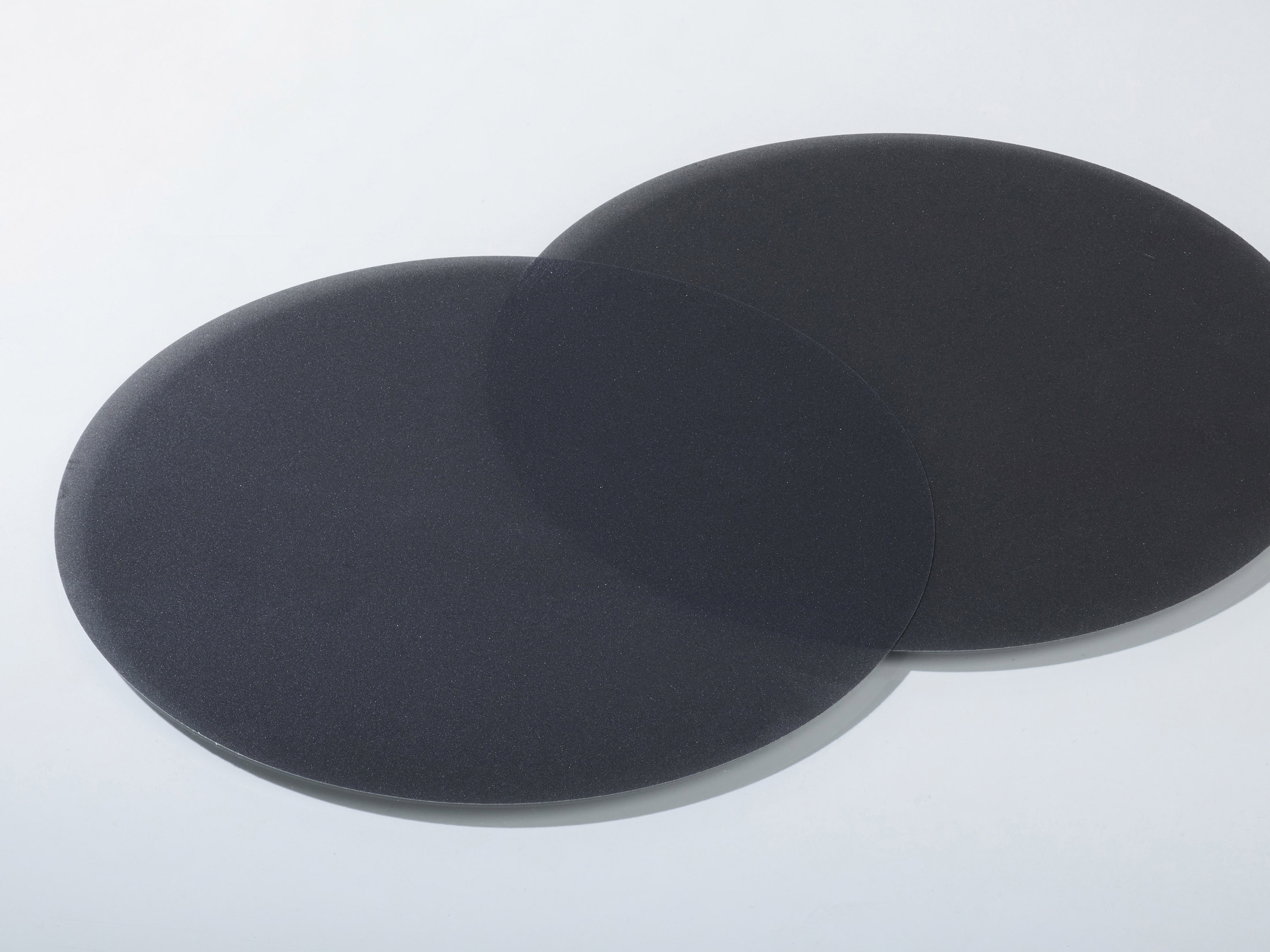

1A-DLF Discs

Our 1A–DLF Discs are fine grinding tools, to reach precise surfaces on extremly hard and hardened materials. Discs are mostly used on lapping machines or for manual operations.

backside:

self adhesive | not self adhesive

dimensions:

from ø 102mm – ø 305mm

other sizes according to customers specification

1A-FINISHING FILM (ALUMINUM OXIDE)

1A-FINISHING FILM (ALUMINUM OXIDE)

… is a concentrated aluminum oxide abrasive, precision coated, water resistant and tough polyester film. The bonding of the abrasive particle provides flexibility and a steady hold on the film substrate. It provides a reliable finish on hard surfaces. The resin bond between the particles and the film ensures an absolute permanent and consistent processing of the surface. The integrated aluminum oxide bonds with accuracy onto the polyester backing material. 1A-Finishing Film offers a repeatable precision finish on extremely hard and hardened materials.

Application areas:

- materials: metals, plastic, rubber, wood, composite material, fiber-glass

- work pieces: Cam shafts, crank shafts, paint spot repair, rolls for superfinishing, glasses, chrome rolls, hardened rolls, rubber rolls, ball bearings, hydraulic components, hardened rollers, steering rod, lenses, oxide panes, plasma coated rolls, pneumatic components, shock absorber, watch components, valves, racks, ceramic and chrome-plated work pieces

- industries: automotive industry, roller manufacturer, roller coating services, ophthalmic industry, watch manufacturer, wood industry, etc.

Grit sizes in µm

9 · 12 · 15 · 20 · 30 · 40 · 50 · 60 · 80 · 100

Abrasives: aluminum oxide – electrostatically spread

Backing material:

polyester foil (5Mil = 125µm und 3Mil = 75µm)

Further information on request.

Our 1A–Finishing Films (Alox) should be generally used in combination with common cooling lubricants or with water.

1A–FF (ALOX) Rolls

backside:

with/ without anti-slipping-backing (ARB)

Abrasive Side:

outside (standard) | inside also possible

dimensions:

standard 100mm x 50m

other sizes according to customers specification

core:

3 inch with notches or 1 inch

1A–FF (ALOX) Sheets

Our 1A–FF (Alox) Sheets are fine grinding tools, to reach precise surfaces on extremly hard and hardened materials. Sheets are mostly used on lapping machines or for manual operations.

backside:

self adhesive | not self adhesive

dimensions:

standard 230mm x 280mm

other sizes according to customers specification

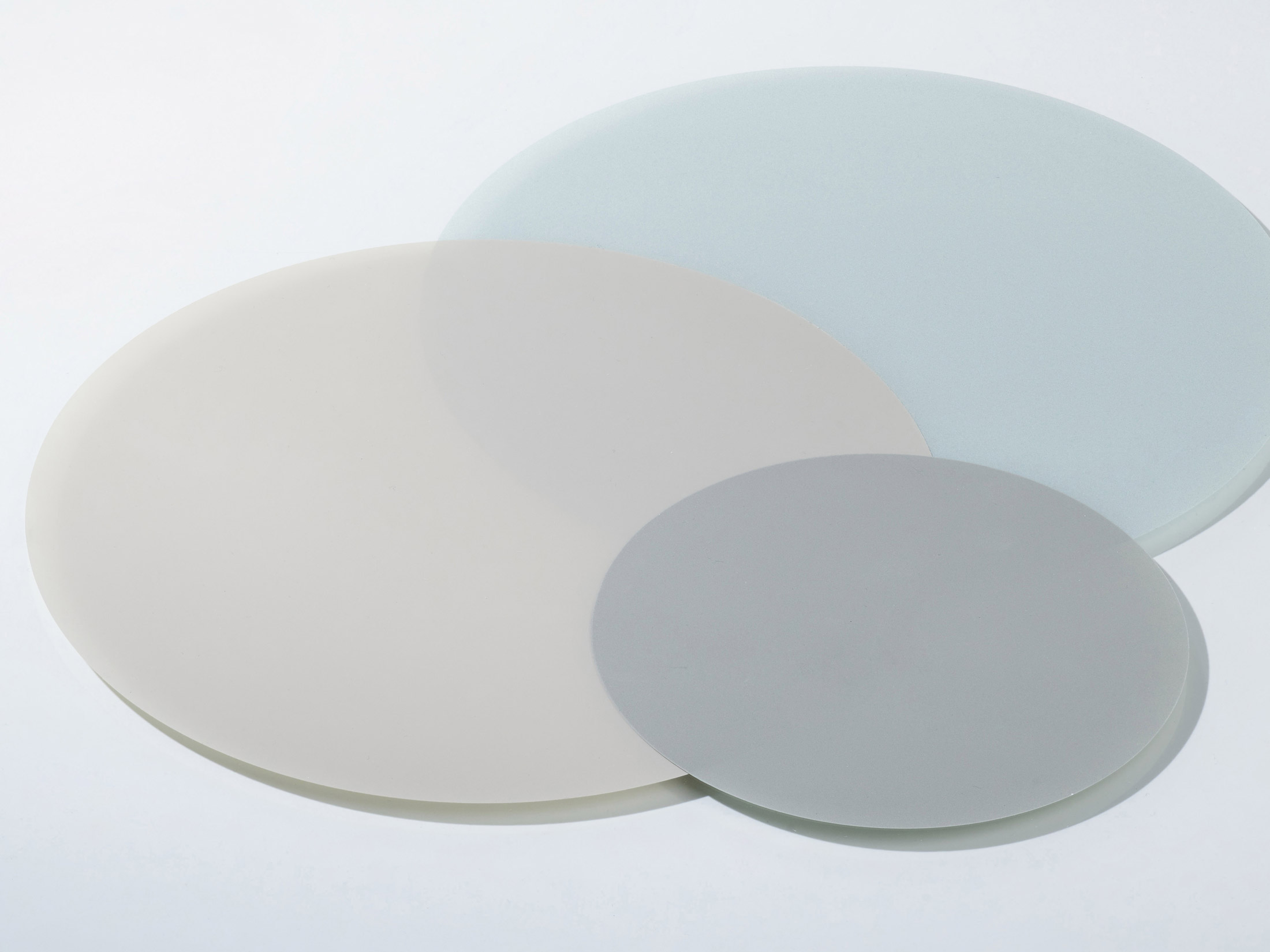

1A–FF (ALOX) Discs

Our 1A-FF (Alox) Discs are fine grinding tools, to reach precise surfaces on extremly hard and hardened materials. Discs are mostly used on lapping machines or for manual operations.

backside:

self adhesive | not self adhesive

dimensions:

from ø 102mm – ø 305mm

other sizes according to customers specification

1A-LAPPING FILM (ALUMINUM OXIDE)

1A-LAPPING FILM (ALUMINUM OXIDE)

… is suitable for industrial processing of metal and non-metal surfaces. The water resistant and tough polyester film is combined with a flexible abrasive slurry coating of aluminum oxide grit for nano-fine, constant polishing. Our bonding system and the consistent grit size ensures the processing of reliable and uniform surfaces. The use of 1A-Lapping Film – from coarse to fine, eliminates the need to contain and remove polishing slurries and polishes to a finer and defined surface finish on hard materials.

Application areas:

- materials: plastic, hardwood, metals, non-ferrous metals, glass, rubber, gem stones

- work pieces: Fiber optic connectors, magnetic heads, windshields, CDs, thin film discs, oxide discs, floppy discs, gear and train components, optic connectors, metallographic preparations, engine and machine parts, chrome rollers, hardened rollers, hydraulic components, pneumatic components, ball bearings, watch components, ceramic and chrome plated work pieces

- industries: ophthalmic and fiber optic industry, automotive industry, roller manufacturer and roller coating services, rolls in the printing and paper industries, watch industry

Grit sizes in µm

0,3 · 0,5 · 1 · 2 · 3 · 5 · 9 · 12 · 15 · 20 · 30 · 40

Abrasives: aluminum oxide – slurry coated

Backing material:

polyester foil (3Mil = 75µm)

Further information on request.

Our 1A–Lapping Films (Alox) should be generally used in combination with common cooling lubricants or with water.

1A–LF (ALOX) Rolls

outside (standard) | inside also possible

dimensions:

standard 100mm x 50m

other sizes according to cutomers spcification

core:

3 inch with notches or 1 inch

1A–LF (ALOX) Sheets

Our 1A–LF (Alox) Sheets are fine grinding tools, to reach precise surfaces on extremly hard and hardened materials. Sheets are mostly used on lapping machines or for manual operations.

backside:

self adhesive | not self adhesive

dimensions:

standard 230mm x 280mm

other sizes according to cutomers spcification

1A–LF (ALOX) Discs

Our 1A–LF (Alox) Discs are fine grinding tools, to reach precise surfaces on extremly hard and hardened materials. Discs are mostly used on lapping machines or for manual operations.

backside:

self adhesive | not self adhesive

dimensions:

from ø 102mm – ø 305mm

other sizes according to customers specification

1A-FINISHING FILM (SILICON CARBIDE)

1A-FINISHING FILM (SILICON CARBIDE)

…is a with concentrated silicon carbide abrasives precision coated, water resistant and tough polyester film. The bonding of the abrasive particle provides flexibility and a steady hold on the film substrate. The resin bond between the particles and the film ensures an absolute permanent and consistent processing of the surface. Our 1A-Finishing Film (SiC) offers a repeatable and precise finish on hard and soft surfaces and provides an aggressive grinding pattern.

Application areas:

- materials: rubber, plastic, glass, stone, wood, metal, non-ferrous metal, composite, plexiglass

- work pieces: rubber rollers, plastic rollers, teflon rollers, lacquer parts, wooden parts

- industries: roller manufacturer, roller coating service, automobile industry, print- and paper industry, instrument manufacturer, furniture industry, stone industry

Grit sizes in µm

9 · 15 · 20 · 30 · 40 · 60 · 80

Abrasives: silicon carbide – electrostatically spread

Backing material:

polyester foil (4Mil = 100µm)

Further information on request.

Our 1A–Finishing Films (SiC) should be generally used in combination with common cooling lubricants or with water.

1A–FF (SiC) Rolls

backside:

with anti-slipping-backing (ARB)

abrasive side:

outside (standard) | inside also possible

dimensions:

standard 100mm x 50m

other sizes according to customers specification

core:

3 inch with notches or 1 inch

1A–FF (SiC) Sheets

Our 1A–FF (SiC) Sheets are fine grinding tools, to reach precise surfaces on extremly hard and hardened materials. Sheets are mostly used on lapping machines or for manual operations.

backside:

self adhesive | not self adhesive

dimensions:

standard 230mm x 280mm

other sizes according to customers specification

1A–FF (SiC) Discs

Our 1A-FF (SiC) Discs are fine grinding tools, to reach precise surfaces on extremly hard and hardened materials. Discs are mostly used on lapping machines or for manual operations.

backside:

self adhesive | not self adhesive

dimensions:

from ø 102mm – ø 305mm

other sizes according to customers specification

1A-LAPPING FILM (SILICON CARBIDE)

1A-LAPPING FILM (SILICON CARBIDE)

…is suitable for industrial processing of metal and non-metal surfaces. The water resistant and tough polyester film is combined with a flexible abrasive slurry coating of silicon carbide grit for nano-fine, constant polishing.

Our bonding system and the consistent grit size ensures the processing of reliable and uniform surfaces. The use of 1A-Lapping Film – from coarse to fine, eliminates the need to contain and remove polishing slurries and polishes to a finer and defined surface finish on hard materials.

Application areas:

- materials: plastic, hardwood, metals, non-ferrous metals, glass, rubber, gem stones

- work pieces: Fiber optic connectors, magnetic heads, windshields, CDs, thin film discs, oxide discs, floppy discs, gear and train components, optic connectors, metallographic preparations, engine and machine parts, chrome rollers, hardened rollers, hydraulic components, pneumatic components, ball bearings, watch components, ceramic and chrome plated work pieces

- industries: ophthalmic and fiber optic industry, automotive industry, roller manufacturer and roller coating services, rolls in the printing and paper industries, watch industry

Grit sizes in µm

1 · 3 · 5 · 9 · 15 · 30

Abrasives: silicon carbide – slurry coated

Backing material:

polyester foil (3Mil = 75µm)

Further information on request.

Our 1A–Lapping Films (SiC) should be generally used in combination with common cooling lubricants or with water.

1A–LF (SiC) Rolls

abrasive side:

outside (standard) | inside also possible

dimensions:

standard 100mm x 50m

other sizes according to cutomers spcification

core:

3 inch with notches or 1 inch

1A–LF (SiC) Sheets

Our 1A–LF (SiC) Sheets are fine grinding tools, to reach precise surfaces on extremly hard and hardened materials. Sheets are mostly used on lapping machines or for manual operations.

backside

self adhesive | not self adhesive

dimensions:

standard 230mm x 280mm

other sizes according to cutomers spcification

1A–LF (SiC) Discs

Our 1A–LF (SiC) Discs are fine grinding tools, to reach precise surfaces on extremly hard and hardened materials. Discs are mostly used on lapping machines or for manual operations.

backside

self adhesive | not self adhesive

dimensions:

from ø 102mm – ø 305mm

other sizes according to customers specification